-

Chemical Processing Tanks

Dennerik has fabricated non-sanitary-grade stainless steel tanks for local partners in chemical and food industries. Tanks can be made to almost any requested grade (304L, 316L, 2250, 2507, etc.) and we also provide on-site services for measuring access dimensions and assisting with installation.

-

Mix Tanks

Over the years, Dennerik has designed, fabricated, and supplied dozens of custom mixing tanks for applications like paint, food, chemical processing, food waste, mine slurry, and many more. We work with local agitator suppliers to match the correct equipment for your application

-

Insulated and Clad Storage Tanks

Dennerik also provides insulated and clad tanks. In this project, we designed, fabricated, coated, insulated, and clad this tank for a local bulk terminal, all at our facility in Maple Ridge.

-

Heated Wax Tank

Design and fabrication of heated, insulated, clad tank for storing liquid wax for use in producing wood products

-

SS Cadmium Sponging Tank

Dennerik undertook the structural design and fabrication of a replacement cadmium sponging tank for a Canadian zinc producer. The tank has unique blow-out panels that will break and release pressure in the event of an explosion. Dennerik supplied the original tank to the client over 25 years prior to its modern replacement.

-

Groundwater Treatment Plant Tanks

The Dennerik team undertook structural engineering, detail design, shop fabrication, and coating of 6 API 650 process tanks and a large stiffened flat plate rectangular tank to enable the treatment of contaminated groundwater in the city of Trail, BC

-

Pacific Coast Terminals Clarifier

Equipment design team collaborator, structural engineering, detail design, shop fabrication in 4 major sections, shipping to site and field erecting a 50’ diameter 304 SS clarifier. Using our in-house prefabrication and erection method, the clarifier was erected on site in less than 1 week.

-

Vancouver Airport Diesel Fuel Tanks

Dennerik participated in guiding the most economical sizing and arrangement for 3 – 380,000 L Diesel Fuel Tanks for YVR. The Dennerik team undertook structural engineering, detail design, and shop fabrication of each tank in 6 very large sections sized to enable special road transport and very quick and low impact site erection.

-

Acid Thickener

Dennerik performed detail design and shop fabrication of a 60 ft. diameter 316 SS Clarifier/Thickener for a mine process plant, in 8 major sections. Including he supply of an embedded ring to allow the proper anchoring of the tank shell.

-

Western Potash

Design and fabrication of a custom large-scale industrial water heater, using proprietary technology. Tank and heating components use Duplex and Super-Duplex alloys like Zeron-100 and Alloy 625 to withstand the intense corrosive environment of heated potash brine.

-

Subsea Cable Laying System

Equipment design collaborator, structural engineering, shop fabrication, and site assembly onto customer’s barge of a rotating 2500 MT 60’ diameter cable turntable with 5 hydraulic drives, overhead conveyor, and traction device. The design intent was met, and the company successfully used to barge to lay a large undersea cable in the New York area

-

SS Swimming Pool

Structural engineering, detail design, shop fabrication in one piece, and finishing of a custom 18′ x 40′ stainless steel swimming pool, with sloping deep end, built in stairs, and ladder footholes. The pool was delivered to the waterfront building site and lifted onto the concrete pad using a large crane. It is completely self-standing and rests on a concrete pad with fantastic views of the Fraser River.

-

Downtown Utility Bridge

Design, fabricate and erect of a 150 foot long utility support bridge for a new multipurpose tower in downtown Vancouver. The excavation went through an alley with buried Hydro, phone, gas, and steam lines, and the truss successfully suspended the live utilities across the open pit excavation while a 9-story deep parkade was excavated beneath it. Slideshow and video here.

-

Sonic Environmental – PCB Extraction Plant

Equipment design and plant layout collaborator, structural engineering, detail design, supply, and shop fabrication of a soil remediation plant comprised of a series of large interlocking modules equipped with API 650 tanks, pumps, heat exchangers, piping, electrical, and other process equipment. This design concept enabled the plant modules to be disassembled and moved from site to site as the stockpile of contaminated soil was depleted.

-

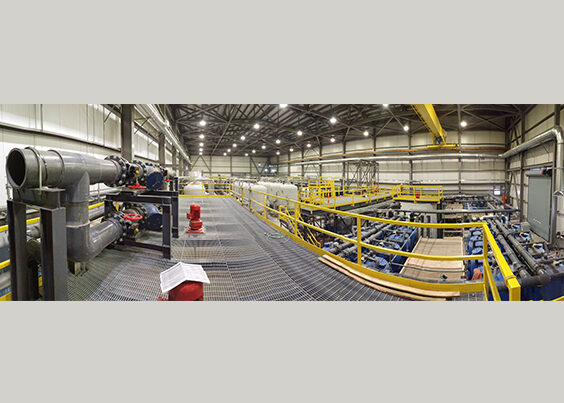

Kemess Mine – Specialized Water Remediation

The Dennerik team undertook the detail equipment design, structural engineering, skid fabrication, tank fabrication, coating, equipment assembly, piping, and electrical of 14 large modules for this EGBC award winning mine water processing plant

The plant’s modules needed to be fabricated and assembled in our Maple Ridge plant, and then transported to site.

-

Minto Mines

Equipment design collaborator, structural engineering, detail design, shop fabrication, equipment assembly, piping, electrical, coating, and test assembly of 7 skid modules to treat mine water. Skids were pre-assembled at our Maple Ridge facility to minimize on-site labour and troubleshooting.