-

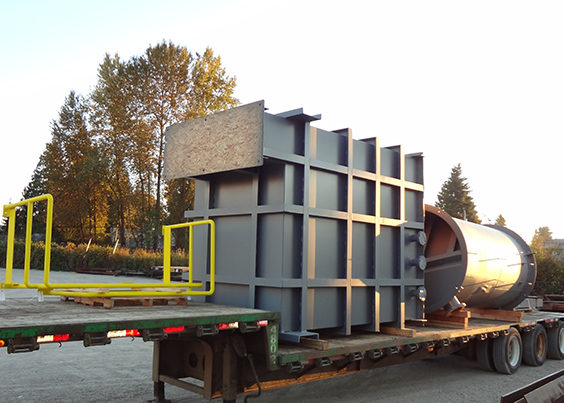

Shell LNG Plant – Kitimat, BC

Equipment design team collaborator, structural engineering, supply, fabrication, inspection, testing, sandblasting, coating, and quality control of 5 large wastewater treatment process tanks for 2000 man construction camp.

-

Capital Regional District

Equipment design team collaborator, structural engineering, detail design, supply, fabrication, inspection, testing, coating, and quality control of CS Sludge Digester for Ganges Wastewater Treatment Plant.

-

Lluvia De Oro, Mexico

Equipment design and plant layout collaborator, structural engineering, detail design, supply, shop fabrication, and site erection of a series of CS and SS process tanks, mixing tanks, CS clarifier, SS clarifier, access walkways and stairs, for a contaminated mine wastewater treatment plant in Sonora, Mexico.

-

Kukio, Hawaii

Design collaborator, structural engineering, detail design, supply, fabrication, inspection, and finishing of Aluminum wastewater process tanks

-

Strata Gold

Design, fabricate, and coat over 1 million pounds of platework for a new gold mine in BC. Our supply was centered around the secondary and tertiary crushers, and included AR-400 liner plates and White Chrome Iron cast liners. Videos of the construction can be seen here.

-

Rubicon Minerals Phoenix Gold Project

Detail design, supply, fabrication, and coating of a large platework and chute package for a new gold mine in Ontario.

-

Gibraltar Taseko Mines

Detail design, supply, fabrication, and coating of a large platework and chute package for a copper molybdenum mine expansion in British Columbia.

-

Copper Mountain Mining Corporation

Structural engineering, detail design, supply, fabrication, coating, and inspection of a very large chutework package for crusher expansion at existing mine in British Columbia.

-

CNRL – Rubber Lined Mix Chutes

Design and supply of rubber-lined mix chuted for use in oil processing. Design included consumable drop-in liners that could be replaced at end of life.

-

Various API-650 Tanks

The Dennerik team has extensive engineering capabilities, design knowledge, and four decades of fabrication history with API, AWWA, and UL code process tanks in CS, SS, Duplex SS, Inconel, and Aluminum. We have a vast suite of the required ASME weld procedures and the certified welders necessary to execute your next project.

-

Diesel Fuel Tanks

Dennerik participated in guiding the most economical sizing and arrangement for 3 – 380,000 L Diesel Fuel Tanks for YVR. The Dennerik team undertook structural engineering, detail design, and shop fabrication of each tank in 6 very large sections sized to enable special road transport and very quick and low impact site erection.